Fluoropolymers such as PTFE are made using PFAS chemicals and are themselves a type of PFAS. The chemistry of making PTFE is inherently problematic because of the hazardous PFAS chemicals it requires; their persistence once released into the environment; the extremely low levels acceptable in drinking water; and the exceptional challenge of cleaning up water or soil once contaminated. These problems arise from PTFE manufacturing even in different locations with different regulations.

To illustrate, we dug deep into the supply chain of two PTFE-coated pans tested in our study (also available as Appendix A in the full report). One supply chain is in the United States and one is largely in Asia. To limit the research scope, the first step we considered was production of the fluorosurfactants needed to produce PTFE. We did not include further upstream processes, including production of the PTFE monomer, tetrafluoroethylene, or its precursor materials.

The two products were chosen based on our ability to access information about their supply chains. Their selections are not meant to imply that they are worst-case examples or unique compared with other nonstick pans we tested.

The second case study turned up the problem of workplace safety in pan production factories in China. These issues impact workers both in non-stick and uncoated pan factories and are described in a third case study here (as well as in Appendix B of the full report).

- Case Study I: A muffin pan made in the U.S.A. is linked to water pollution in three states

- Case Study II: A nonstick skillet made in China represents a complex global supply chain and toxic workplaces

Case Study I: A muffin pan made in the U.S.A. is linked to water pollution in three states

The ProBake Nonstick 12-Cup Muffin Pan by G&S Metal Company was one of two pans we tested that was made in the United States. It is labeled as “TEFLON Xtra Nonstick.” The PTFE coating we identified on the muffin pan represents the end of a supply chain that releases highly toxic pollution in three states:

- North Carolina: Chemours produces GenX, a surfactant necessary for making PTFE, at its Fayetteville Works plant. GenX is a substitute for PFOA, one of the best-studied toxic PFAS. The Fayetteville plant has discharged toxic GenX into the local river for decades. It has contaminated residents’ drinking water.

- West Virginia: Chemours ships GenX from Fayetteville to its Washington Works plant near Parkersburg, WV, where it uses the compound in the manufacture of Teflon™ (PTFE). The area’s water is now contaminated with GenX in addition to the PFOA left from earlier decades.

- Connecticut: G&S purchases PTFE mixtures from Chemours and uses them to coat steel at a coil coating plant in Hamden, CT. This plant is a serial polluter of water, although we lack information on the fate of PFAS chemicals used at this plant because these chemicals are not monitored. The PTFE-coated steel is then shipped to Cleveland to be stamped into cookware like muffin pans and sold at retailers like Amazon and Walmart.

Plants in this chain--Fayetteville NC, Parkersburg WV, and Hamden CT--release PFAS and other toxic chemicals into workplaces and out their stacks and pipes into surrounding communities. A deeper look into each location follows.

-

Chemours (formerly DuPont), Fayetteville, North Carolina

DuPont discharged GenX into the air and water around Fayetteville starting in the 1980s. In 2015, DuPont spun off the Fayetteville plant and the rest of its fluorochemicals business into a company that it created called Chemours.[1]

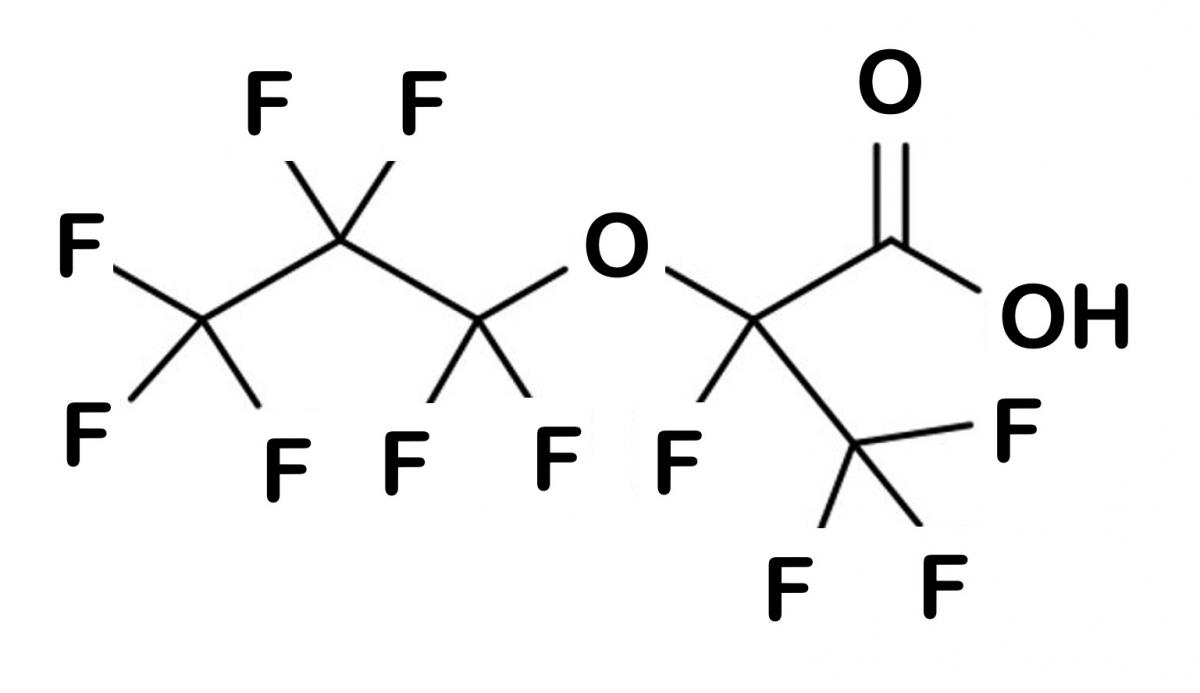

GenX is Chemours’ trade name for hexafluoropropylene oxide-dimer acid or HFPO-DA (CAS number 13252-13-6), or its ammonium salt.[2] As of 2016 (and likely, at any time), Chemours was the only manufacturer of this chemical in the United States. The company filed a report with EPA stating that it manufactured 535,619 pounds of GenX liquid in 2015.[3]

In 2017, the North Carolina Department of Environmental Quality announced it had “ordered Chemours to stop releasing all fluorinated compounds [including GenX] into the Cape Fear River and began legal action against the company and the process to suspend its permit for discharging wastewater into the river.”[4]

In February 2018, residents sued DuPont and Chemours, saying that GenX could be even more toxic than PFOA. They alleged that “DuPont overlooked the results of its own testing on GenX and illegally discharged the chemical into North Carolina’s Cape Fear River from its Fayetteville Works plant and lied to government regulators, claiming it was disposing of GenX safely when in fact it was not.”[5] The case is in discovery as of this writing.

In 2020, in a separate case, Chemours agreed to stop “99% of GenX and other PFAS water pollution from the most significant sources of pollution at its site into the Cape Fear River,” according to the Southern Environmental Law Center.[6]

GenX chemical structure.

Chemours has no plans to reduce production of GenX, but says it has made strides in preventing discharge to the environment. The company was “required by consent order to have a thermal oxidizer installed by December 31, 2019 to control PFAS process stream emissions” from its facility. The company reports the thermal oxidizers are installed and are destroying GenX and forming hydrogen fluoride, which is captured, neutralized, and eventually landfilled.[7]

-

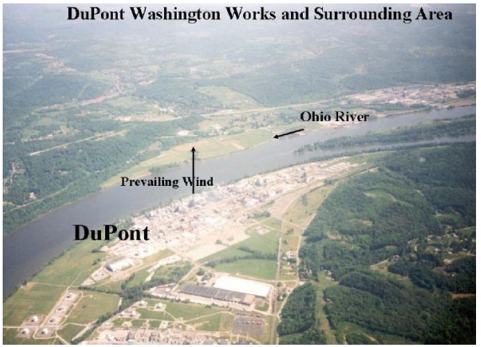

Chemours (formerly DuPont), Parkersburg, West Virginia

From North Carolina, Chemours ships GenX to its Teflon (PTFE) factory near Parkersburg, West Virginia called Washington Works.[9] This is where the PTFE on the G&S muffin pan we tested was produced.

The Washington Works plant is Chemours’ largest and has been making fluorochemicals since 1950. The plant produces many forms of Teflon-branded fluorochemicals, including perfluoroalkoxy (PFA) dispersions and resins (used in chemical processing equipment and industrial bakeware)[10] and PTFE resins and dispersions, including those used in cookware and bakeware.[11]

Historically, much of Washington Works’ PTFE production utilized PFOA as a surfactant. The plant’s releases of PFOA have harmed the health of workers and their children, polluted residents’ drinking water supplies, and contaminated farms where DuPont dumped PFOA-laden waste. A scientific panel recently found “probable links” between this factory’s production of PFOA and severe health impacts on residents, including high cholesterol, kidney cancer, pregnancy-induced hypertension, testicular cancer, thyroid disease, and ulcerative colitis.[12]

The 2018 documentary, The Devil We Know, exposes the cumulative impacts of PFOA production on the community.[13] But by the time of that film’s release, a lesser known devil--GenX--was emerging in the drinking water around Washington Works.

In 2013, when DuPont replaced PFOA with GenX, it hailed the chemical as a “more sustainable solution…with a favorable toxicological profile and very rapid bioelimination.”[14] Unfortunately, recent research reveals that GenX, like PFOA, shows very high persistence and transport in water and potential human health harm; for these reasons, the European Union has listed GenX as a possible substance of very high concern.[15]

By 2018, EPA had raised concerns about the discharge of GenX into the same water supplies around Parkersburg that were earlier contaminated by PFOA. EPA Water Protection Division Acting Director Kate McManus wrote,

EPA understands that DuPont and Chemours replaced PFOA with the compound GenX...EPA requests that Chemours sample a select group of public and private drinking water supplies for GenX in the vicinity of the Washington Works facility. The water supplies...were chosen by EPA based upon their historically high concentrations of PFOA. It is likely that these same wells would be impacted by GenX...[16]

In response to EPA’s request, Chemours indeed detected GenX in well water in nine of 14 wells sampled in West Virginia and Ohio.[17]

In February 2019, EPA issued a Notice of Violation to Chemours for violating the Toxic Substances Control Act (TSCA). The public version of this notice is highly redacted.[18] A sanitized explanation of this notice does not even name GenX.[19] However, the EPA Inspector General, in a 2020 review of EPA GenX policy, said these violations were related to this chemical.”[20]

-

G&S Metal Products / Porcelain Specrail (Hamden, Connecticut)

The next stop on the path to a finished muffin pan is Hamden, CT. A PTFE dispersion from Chemours’ Washington Works plant is shipped to a factory in Hamden owned by G&S Metal Products and its affiliated company, Porcelen Specrail. There, the PTFE is sprayed onto coils of steel.[22]

G&S Metal Products is the largest producer of metal bakeware in the United States.[23] “G&S offers several different lines of bakeware with Teflon® branded coatings,” notes its website.[24]

According to workers at the plant, they coat up to 28 coils of steel per day, five days a week. The steel is primed, then coated, cured in an oven, then quenched with water.

The Hamden coil coating plant is a serial polluter of Connecticut’s water. The plant has been out of compliance with Clean Water Act regulations for six of the last eight quarters.[25] It discharges wastewater containing hexavalent chromium, lead, and cyanide to a public wastewater treatment plant on New Haven Harbor.[26]

We do not know, however, whether pollutants from the Hamden plant include PFAS chemicals. EPA does not consider PFAS in its regulations for effluent from coil coating operations, which have not been updated since 1983.[27]

In addition to clean water violations, workers at Porcelen Specrail have also have faced unsafe working conditions. In 2012, OSHA found the company in serious violation of respiratory protection dust standards for barium sulfate and titanium dioxide in 2012.[28]

After applying the nonstick finish, G&S ships the coated coils to Cleveland, Ohio, where they are stamped into products like muffin pans and packaged for distribution to companies like Amazon, Sears,[29] and Walmart.[30]

The Hamden operation is not G&S’s only source for PTFE-coated cookware. In 2020, G&S imported more than 210 tons of “Aluminum Teflon Skillets/Saucepans” from an undisclosed company in China.[31]

Case Study II: A nonstick skillet made in China represents a complex global supply chain and toxic workplaces

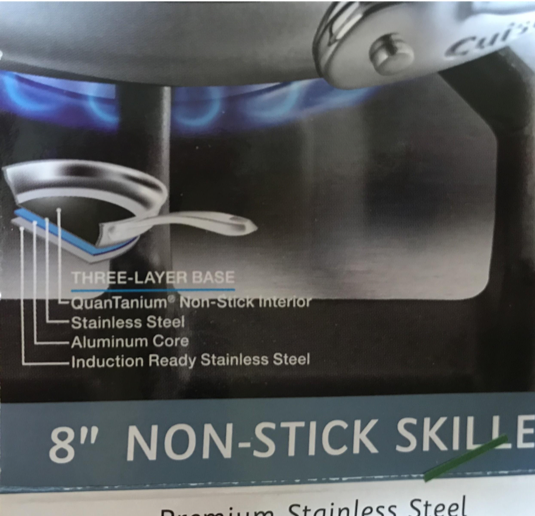

We confirmed the presence of PTFE in a Cuisinart Classic stainless steel 8 in. non-stick skillet that was made in China and sold by Target. Cuisinart is a division of Conair, a privately held company with headquarters in East Windsor, New Jersey.[32] Conair, which also sells cookware under the Waring brand, sells $2 billion worth of household and personal appliances per year.[33] Conair buys most of its products from factories in East Asia.[34]

The supply chain for the PTFE coating on this pan was difficult to uncover. Although we were not able to pinpoint precise facilities for several steps, our research demonstrated the evidently universal links between fluoropolymer manufacture and the release of toxic PFAS into the environment.

A snapshot of four major steps in the chain is below, followed by more details.

- Unknown location: A non-PFOA surfactant is produced. Although created to replace PFOA, these alternatives are proving both persistent and toxic. The surfactant may be produced in an agricultural region of China, a Chemours factory in North Carolina, or another location.

- India, China, or the U.S.: A PTFE dispersion is produced using the above surfactant. The most likely manufacturers are Gujarat Fluorochemicals Ltd.(GFL) in India, Dongyue Group in China or Chemours in West Virginia.

- Possibly Zhuhai, China: The PTFE dispersion from step 2 is shipped to a fluoropolymer blending facility owned by Whitford Worldwide, where PTFE is blended with additives to make Whitford’s brand of PTFE called QuanTanium.

- Xinxing County, China: QuanTanium is purchased by the Guangdong Master Group Stainless Steel Company. The Guangdong plant sprays the blend onto Cuisinart-branded metal pans. This plant has an abysmal record of worker safety. The finished Cuisinart nonstick skillets are shipped to retailers like Target, Macy’s, and Bed Bath & Beyond.

Following is a deeper look into what we learned.

-

Non-PFOA surfactant production

Fluorosurfactants are essential process aids in PTFE production. The surfactant used for the coating on the Cuisinart skillet may be a form of HFPO (hexafluoropropylene oxide), a fluorochemical originally developed by Chemours to replace PFOA. Chemours’ HFPO-based surfactants are called GenX. A few other companies make similar fluorosurfactants.[35] The pan’s package states the coating is “QuanTanium,” and according to Whitford Worldwide, owner of the QuanTanium brand, these coatings are based on “PFOA-free” PTFE.[36]

HFPO-based surfactants are produced by Chemours in Fayetteville, North Carolina and Dordrecht, Netherlands (both producing GenX) and by the Dongyue Group in Shandong Province, China, also called Shandong Dongyue Polymer Material Co. (producing at least one variety of HFPO).[37] The latter is a massive, and massively polluting, fluorochemical production center.

These far-flung facilities have contaminated the surrounding waterways with fluorosurfactants. PFAS chemicals from manufacturing even come down with the rain after being released into the air.[38]

Chemours’ Fayetteville plant in the U.S. released GenX into the Cape Fear River and into the air for years and has only recently been forced by regulators to try to capture and destroy the chemical.[39]

-

India, China, or United States PTFE production

A PTFE dispersion is produced using a fluorosurfactant from step 1. Again, the Dongyue Group production center is a possible source, as are Gujarat Fluorochemicals Ltd.(GFL) in India and Chemours in Parkersburg, West Virginia. All these facilities produce PFOA-free PTFE like that on the Cusiniart pan.

The company that will purchase the PTFE made in this step, Whitford Worldwide, is a frequent customer of GFL. In 2020, through October, Whitford in China imported 235 metric tons of PTFE dispersions from GFL in India.[40]

PTFE production is known to cause nearly intractable pollution of local waterways, soil, and air. PFAS pollution in India has been little studied, while environmental contamination, human exposure and health impacts from the Chemours and Dongyue Group facilities have been studied by a number of research groups.[41]

Runoff from Dongyue Group’s massive factory complex has severely polluted the nearby rivers and soil with HFPO-derived based fluorosurfactants.[42] PFOA, which the facility also uses, and other hazardous PFAS were detected in wheat and maize grown in the area, a major grain-producing region. Researchers concluded that exposure “via the consumption of contaminated grains represents a health risk for local residents, especially for toddlers and children.”[43]

Multiple investigations “provide indisputable evidence that Chinese [fluoropolymer] manufacturers employ both alternative PFASs and APFO as processing aids.”42

-

Whitford Worldwide blending facility, possibly in Zhuhai, Guangdong Province

Whitford Worldwide in 2018 claimed to be the “largest, most complete” fluoropolymer coating manufacturer in the world.[44] PPG, one of the oldest chemical companies in the United States, acquired Whitford last year.[45]

Whitford owns several fluoropolymer blending facilities, including in Jiangmen and Zhuhai, China,[46] in the heart of the Pearl River Delta. PTFE purchased from a supplier (step 2 above) is blended with titanium to make Whitford’s coating brand called QuanTanium, specifically for metal cookware.

“Whitford purchases several thousand metric tons of fluoropolymers, such as PTFE, annually for use as raw materials in coating formulations,” explained Mike Haley, a company manager, in 2011.[47]

-

Guangdong Master Group Stainless Steel Company

Not far from Whitford Worldwide’s Zhuhai and Jiangmen factories in the heart of the Pearl River Delta, a large skillet factory owned by Guangdong Master Group Stainless Steel Company operates near the confluence of several rivers. The facility is in Xinxing Township in Guangdong Province.

QuanTanium is shipped to this Guangdong plant, where workers polish skillets, apply adhesive to the interior, then spray QuanTanium onto Cuisinart-branded metal pans.[48] The finished Cuisinart nonstick skillets are shipped to retailers like Target, Macy’s, and Bed Bath & Beyond.

We did not find information on environmental contamination around this plant, but we did discover an abysmal record of worker safety, detailed in Appendix B.

Endnotes

[1] Chemours Investor Relations. “DuPont Completes Spin-off The Chemours Company,” July 1, 2015. https://investors.chemours.com/news-releases/news-releases-details/2015/DuPont-Completes-Spin-off-of-The-Chemours-Company/default.aspx.

[2] Lauren Mullin et al., “Analysis of Hexafluoropropylene Oxide-Dimer Acid (HFPO-DA) by Liquid Chromatography-Mass Spectrometry (LC-MS): Review of Current Approaches and Environmental Levels,” Trends Analyt Chem, no. 118 (2019): 828–839. and “GenX,” Pharos Project, n.d., https://pharosproject.net/chemicals/2098681#hazards-panel. See also: Galloway, J., A. Moreno, A. Lindstrom, M. Strynar, S. Newton, A. May, AND L. Weavers. Evidence of Air Dispersion: HFPO-DA and PFOA in Ohio and West Virginia Surface Water and Soil Near a Fluoropolymer Production Facility. Environ. Sci. Tech., 54(12):7175-7184, (2020). https://doi.org/10.1021/acs.est.9b07384.

[3] Chemical Data Report as published in EPA Chemview database, https://chemview.epa.gov/chemview/#, December 4, 2020.

[4] “State Orders Chemours to Stop Chemical Releases, Begins Legal Action and Steps to Suspend Permit,” North Carolina Environmental Quality, 9/5/, https://deq.nc.gov/news/press-releases/2017/09/05/state-orders-chemours-stop-chemical-releases-begins-legal-action-and.

[5] “Cape Fear River, NC Water Contamination Litigation: Carey, et al., v. E.I. DuPont De Nemours and Co., Inc., et al,” CohenMilstein, 2020, https://www.cohenmilstein.com/case-study/carey-et-al-v-ei-du-pont-de-nemours-and-co-inc-et-al-cape-fear-river-nc-water.

[6] “N.C. Court Approves Agreement for 99% Reduction of Chemours’ GenX & Other PFAS Water Pollution,” Press Release, Southern Environmental Law Center, October 13, 2020, https://www.southernenvironment.org/news-and-press/press-releases/99-reduction-of-chemours-pfas-pollution-agreement-approved.

[7] “THERMAL OXIDIZER PERFORMANCE TEST REPORT CHEMOURS COMPANY FAYETTEVILLE WORKS,” March 2020. https://www.chemours.com/en/-/media/files/corporate/fayetteville-works/2...

[8] “PFAS and Protection Your Health,” CDC Public Health round Rounds, November 19, 2019, https://www.cdc.gov/grand-rounds/pp/2019/20191119-pfas-health.pdf.

[9] Kate McManus, “Request for Sampling; GenX in Water Supplies,” January 11, 2018, “https://cdn.toxicdocs.org/24/24vqZBgkXwYkdngG4pJpL536/24vqZBgkXwYkdngG4pJpL536.pdf.

[10] “Teflon PFA,” Products, Chemours, n.d., https://www.teflon.com/en/products/coatings/pfa-coatings.

[11] “Choosing the Right Teflon Non-Stick Coating,” Products, Chemours, n.d., https://www.teflon.com/en/consumers/teflon-coatings-cookware-bakeware/choosing-nonstick-coating .

[12] “C8 Science Panel,” C8 Science Panel Website, January 22, 2020, http://www.c8sciencepanel.org/index.html.

[13] Stephanie Soechtig, The Devil We Know, Documentary, 2018, https://thedevilweknow.com/see-the-film/.

[14] “DuPontTM GenX Processing Aid for Making Fluoropolymer Resins” (Dupont, 2010), https://bladenonline.com/wp-content/uploads/2017/06/Chemours_GenX_Brochure_Final_07July2010.pdf.

[15] Lohmann, R. et al. “Are Fluoropolymers Really of Low Concern for Human and Environmental Health and Separate from Other PFAS?” Environ. Sci. Technol. 2020, 54, 20, 12820

[16] Kate McManus, “Request for Sampling; GenX in Water Supplies,” January 11, 2018, https://cdn.toxicdocs.org/24/24vqZBgkXwYkdngG4pJpL536/24vqZBgkXwYkdngG4pJpL536.pdf.

[17] C. Hogue, “GenX-related fluoroether taints water in wells near West Virginia Chemours plant”, Chem. & Eng. News, April 2018. https://cen.acs.org/environment/pollution/GenX-related-fluoroether-taints-water/96/web/2018/04

[18] Lauren Davis, “Notice of Violations for Chemours,” Compliance Monitoring Inspection Report (US Environmental Protection Agency, Region 3, July 31, 2018), https://www.epa.gov/sites/production/files/2019-02/documents/tsca_non_cbi-r3_chemours_inspection_report.pdf.

[19] Diane Saenz, “Notice of Violations of the Toxic Control Substance Act,” US EPA, February 13, 2019, https://www.epa.gov/sites/production/files/2019-02/documents/chemours_tsca_nov_-_cbi_sanitized_-_021318_signed.pdf.

[20] Sarah Davidson et al., “EPA Toxic Substances Control Consent Orders Need Coordination” (US Environmental Protection Agency, May 28, 2020), https://www.epa.gov/sites/production/files/2020-05/documents/_epaoig_20200528-20-e-0177_1.pdf.

[21] “Coil Coating Effluent Guidelines,” U.S. Environmental Protection Agency, n.d. https://www.epa.gov/eg/coil-coating-effluent-guidelines

[22] “Supply Chain,” G&S Metal Products, 2020, https://gsmetal.com/supply-chain/. Porcelain Specrail operates two facilities in Hamden CT. The spray coating occurs at 129 Leeder Hill Drive. EPA’s records for this facility are available here: https://enviro.epa.gov/enviro/airsquery.detail_plt_view?p_id=CT0000000900900090 and https://echo.epa.gov/detailed-facility-report?fid=110000316881.

[23] Porcelen is (was) owned by Robert Goodman (Woodbridge CT) and Mark Schwartz (Moreland Hills OH), according to Connecticut state records. Their last names presumably are the initials for G&S. Mark Schwartz is the sole owner of G&S, according to corporate records filed with the Ohio Sec. of State. https://businesssearch.ohiosos.gov/.

[24] “Teflon Coated Bakeware,” G&S Metal Products, 2020, “Coil Coating Effluent Guidelines,” U.S. Environmental Protection Agency, n.d. https://www.epa.gov/eg/coil-coating-effluent-guidelines https://gsmetal.com/products/teflon-coated-bakeware/.

[25] “Detailed Facility Report -Porce-Len Inc.,” EPA Enforcement and Compliance Online, n.d., https://echo.epa.gov/detailed-facility-report?fid=110000316881.

[26] Oswald Inglese, “Porcelen Limited Pretreatment Permit” (Connecticut Department of Energy and Environmental Protection, 2012), https://www3.epa.gov/region1/npdes/permits/draft/2012/draftsp0000656permit.pdf.

[27] “Coil Coating Effluent Guidelines,” U.S. Environmental Protection Agency, n.d. https://www.epa.gov/eg/coil-coating-effluent-guidelines

[28] “Porcelen Limited Connecticut,” OSHA Violation Detail, November 29, 2012, https://www.osha.gov/pls/imis/establishment.violation_detail?id=504118.015&citation_id=01001.

[29] “G & S Metal Products Company ProBake Teflon Non-Stick 12" Pizza Pan,” Sears, n.d., G & S Metal Products Company ProBake Teflon Non-Stick 12" Pizza Pan.

[30] “G & S Metal Products Company PB64 ProBake Teflon Xtra Nonstick Bake and Roasting Pan,” Walmart, n.d., https://www.walmart.com/ip/G-S-Metal-Products-Company-PB64-ProBake-Teflon-Xtra-Nonstick-Bake-and-Roasting-Pan-15-5-x-10-5-Charcoal/678543294.

[31] Bills of Lading provided to U.S. Customs and Border Protection, as viewed in the Datamyne trade database (subscription site), January 1, 2020 to November 29, 2020.

[32] “Conair Founder Leandro Rizzuto, of Palm Beach, Dies,” Palm Beach Daily News, May 29, 2018.

[33] “Conair,” Forbes, 2020, https://www.forbes.com/companies/conair/?sh=14f08bd2f900.

[34] “CONAIR CORPORATION - Form 10K” (Securities and Exchange Commission, March 29, 1995), https://www.sec.gov/Archives/edgar/data/769208/0000769208-95-000006.txt.

[35] Testimony of Paul Kirsch, The Chemours Company, 2019. https://docs.house.gov/meetings/GO/GO28/20190910/109902/HHRG-116-GO28-Wstate-KirschP-20190910.pdf

[36] “QuanTanium® 7141/ 7242/ 7343” (Whitford Worldwide, 2019), https://www.whitfordww.com/wp-content/uploads/2019/05/BrandFactSheetsTemplate_QuanTanium2019.pdf.

[37] Dongyue Group Ltd. 2019 Annual Report, http://www.dongyuechem.com/UploadFiles/News/2020/04/2100db08-148b-448a-b...

[38] Liu, et al, 2017. “Crop bioaccumulation and human exposure of perfluoroalkyl acids through

multi-media transport from a mega fluorochemical industrial park, China” Environ. Int. 106 (2017) 37–47; Jarvis, Craig. “How long will it take to rid PFAS from private wells?” North Carolina Health News. April 2020. https://www.northcarolinahealthnews.org/2020/04/07/pfas-private-wells/ Accessed 07 Nov 2020

[39] “State Orders Chemours to Stop Chemical Releases, Begins Legal Action...,” North Carolina Environmental Quality, 2017, https://deq.nc.gov/news/press-releases/2017/09/05/state-orders-chemours-stop-chemical-releases-begins-legal-action-and; “N.C. Court Approves Agreement for 99% Reduction of Chemours’ GenX & Other PFAS Water Pollution,” Southern Env. Law Center, October 13, 2020, https://www.southernenvironment.org/news-and-press/press-releases/99-red....

[40] Bills of Lading, Datamyne database (subscription).

[41] Liu, et al, 2017. “Crop bioaccumulation and human exposure of perfluoroalkyl acids through multi-media transport from a mega fluorochemical industrial park, China.” Environ. Int. 106 (2017) 37–47; Xiaowei et al “Emissions, Transport, and Fate of Emerging Per- and Polyfluoroalkyl Substances from One of the Major Fluoropolymer Manufacturing Facilities in China.” Environ. Sci. Tech 52(17) (2018); Sun, M. et al, “Legacy and Emerging Perfluoroalkyl Substances Are Important Drinking Water Contaminants in the Cape Fear River Watershed of North Carolina.” Environ. Sci. Technol. Lett. 2016, 3 (12), 415–419.

[42] Xiaowei et al, 2018 (see above).

[43] Liu, et al, 2017 (see above).

[44] “The Whitford Group of Companies” (Whitford Corporation, 2018), https://www.whitfordww.com/wp-content/uploads/2018/06/Whitford-Worldwide.pdf.

[45] “PPG Complete Acquisition of Global Coatings Manufacturer Whitford Worldwide,” PPG, March 1, 2019, https://news.ppg.com/press-releases/press-release-details/2019/PPG-Completes-Acquisition-of-Global-Coatings-Manufacturer-Whitford-Worldwide/default.aspx.

[46] “QuanTanium® 7141/ 7242/ 7343” (Whitford Worldwide, 2019), https://www.whitfordww.com/wp-content/uploads/2019/05/BrandFactSheetsTem.... ; “Information of Whitford (Jiangmen) Ltd.,” 123th Canton Fair Exhibitor, n.d., https://www.shujukuji.cn/123th-canton-fair-exhibitor/name/13595; “QC Technician,” Whitford, November 9, 2018, https://www.whitfordww.com/careers/qc%e6%8a%80%e6%9c%af%e5%91%98-qc-technician/.

[47] Mike Haley, “Fluoropolymer Pricing Trends - An Unprecedented Situation,” Coatings World, September 13, 2011, https://www.coatingsworld.com/contents/view_experts-opinion/2011-09-13/fluoropolymer-pricing-trends---an-unprecedented-situation/.

[48] China Labor Watch, “Dirty Frying Pans: An Investigation of Labor Abuses in Five Chinese Cookware Factories,” Feb. 2016. http://www.chinalaborwatch.org/report/112