Sample collection

We purchased 10 baking pans and 14 cooking pans from 20 brands and 10 popular retailers, including discount “dollar” stores. We included top cookware brands as identified by Consumer Reports Magazine. For cookware, we only purchased pans described by the manufacturer as nonstick. We did the same for bakeware with the exception of a pizza pan and a cake pan from a Dollar Tree store. The latter two pans appeared to have a coating but their labels did not specify nonstick. We purposely included two nonstick cooking pans claiming to be PTFE-free in order to determine what alternative coating was used.

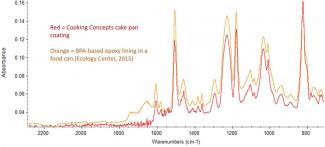

Sample preparation and testing

We scraped bits of surface coating off of each pan with a metal tool. We placed the scrapings onto the stage of a Nicolet iS5 Fourier Transform Infrared (FTIR) spectrometer with an attenuated total reflection (ATR) accessory. Absorbance spectra were collected from 4000-500 cm-1 with 4 cm-1 resolution using Omnic software. To identify materials, we used a combination of visual inspection of the spectral data along with searching for matches in a spectral library purchased from Thermo Scientific. Omnic Specta software was used to help identify mixed polymers. To determine a positive match, we required excellent alignment of peaks in the experimental spectrum with a library spectrum or with a known reference standard.

More about FTIR spectroscopy

The output of FTIR spectroscopy is an absorbance spectrum that is unique to the molecular structure of the material. For example, a polyethylene terephthalate (typical polyester) spectrum is distinct from a polydimethylsiloxane (typical silicone) spectrum. Metal oxides (often called ceramics) such as silicon dioxide also produce identifiable infrared spectra. The data are best interpreted by a spectroscopy expert through a combination of visual verification of absorbance peak positions and patterns and matches to known reference spectra.

The images below illustrate the use of FTIR in identifying pan coatings:

(a) Offset FTIR spectra collected in our lab from a frying pan coated with PTFE (polytetrafluoroethylene) compared to a PTFE powder sample purchased from Sigma Aldrich. The peak positions, widths, and relative intensities are in close agreement.

(b) Offset FTIR spectra collected in our lab from a cake pan coated with BPA-based epoxy (red) compared to the lining of a food can coated with BPA-based epoxy (orange). The food can lining is used here in lieu of a standard reference spectrum. The peak positions, widths, and relative intensities are in close agreement.